china warman froth pump factories

Latest articles

As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreSlurry pump seals

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreDepending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreSlurry pipe diameter.

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreThere are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreWhat are the materials used to construct the pump?

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreThe slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreUnderwater installation

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreA slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read MoreSubmersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

china warman froth pump factories...

china warman froth pump factories 【china warman froth pump factories】

Read More

Popular articles

- Floor drainage

- Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

- There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- Dredge Pump

- As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

Latest articles

-

Positive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

-

For more information about this new and improved pump, please contact us.

-

What is Heavy Duty Slurry Pump?

-

There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

Links

- Hardened drill bits are specialized tools designed to tackle tough drilling tasks that standard drill bits may struggle with. These high-performance bits are heat-treated and hardened to enhance their durability and resistance to wear, making them ideal for drilling through hard materials like stainless steel, cast iron, and even some types of concrete.

- Drill bits are the cutting tools of a rock drill. They come in various shapes and sizes to accommodate different types of rock formations. The design and material of the drill bits are crucial for their performance. Tungsten carbide is a popular material used in drill bits because of its hardness and wear resistance.

- Despite their numerous advantages, FRP ducts do have some limitations that are worth considering

- 3. Regular Maintenance Conduct regular inspections and cleaning of the ducts to remove any dirt, debris, or moisture that may accumulate and contribute to corrosion.

- Lingkungan Industri dan Pabrik: FRP grating sering digunakan di lingkungan industri dan pabrik sebagai lantai pengaman, platform kerja, atau jaring pengaman di sekitar peralatan, mesin, atau area produksi. HI-Grid FRP Grating tahan terhadap korosi dari bahan kimia industri dan memberikan stabilitas yang diperlukan.

- Komposisi Material:

- Furthermore, these tanks exhibit excellent chemical resistance. They can withstand exposure to a wide range of corrosive substances, from acids and alkalis to saltwater and solvents. This characteristic makes them a preferred choice in chemical processing, wastewater treatment, and pharmaceutical industries.

- In the vast landscape of industrial applications, the role of insulation cannot be overstated. Fiberglass pipe insulation fittings are a crucial component in maintaining thermal efficiency and ensuring the durability of piping systems across various sectors such as heating, ventilation, air conditioning (HVAC), and chemical processing. These fittings offer an array of benefits that make them indispensable for both new installations and upgrades to existing infrastructure.

- 3. Budget Consider your budget when choosing a drill. More expensive drills are not always better, but they may offer additional features or higher performance that could save you time and money in the long run.

fiberglass sand pipe. The combination of glass fibers and sand creates a pipe that is less prone to cracking, leaking, or rupturing, thereby ensuring a more reliable and cost-effective piping system in the long run.

fiberglass sand pipe. The combination of glass fibers and sand creates a pipe that is less prone to cracking, leaking, or rupturing, thereby ensuring a more reliable and cost-effective piping system in the long run.AQUATECH CHINA Expo will be held on June 2 – 4, 2021 at National Exhibition Center in Shanghai, China.

Hengshui Jrain, completed a lot of FRP fittings for our Australia customer, and they were loaded from workshop today. Hope their travel oversea is joyful.

Download our Grating Selection Chart to help you find the right type of grating. To help you with load calculations, we have a handy molded grating load table PDF with information on the load capacities of different grating sizes.

rock drill parts.

Uses for Fiberglass Grating

The hard carbon aerogel can maintain the super-elasticity in harsh conditions, such as in liquid nitrogen. Based on the fascinating mechanical properties, this hard carbon aerogel has promise in the application of stress sensors with high stability and wide detective range (50 KPa), as well as stretchable or bendable conductors. This approach holds promise to be extended to make other non-carbon based composite nanofibers and provides a promising way of transforming rigid materials into elastic or flexible materials by designing the nanofibrous microstructures.

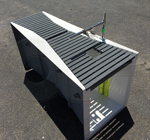

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

Fiberglass Structural Shapes:

frp car body. The manufacturing process can be more complex than traditional metal stamping, requiring specialized equipment and skill sets. There are also concerns about repairability and cost, as FRP components may need to be replaced rather than repaired in the event of damage.

frp car body. The manufacturing process can be more complex than traditional metal stamping, requiring specialized equipment and skill sets. There are also concerns about repairability and cost, as FRP components may need to be replaced rather than repaired in the event of damage.

fiberglass 90 degree elbow. This can lead to longer lifespans and lower maintenance costs for the overall system.